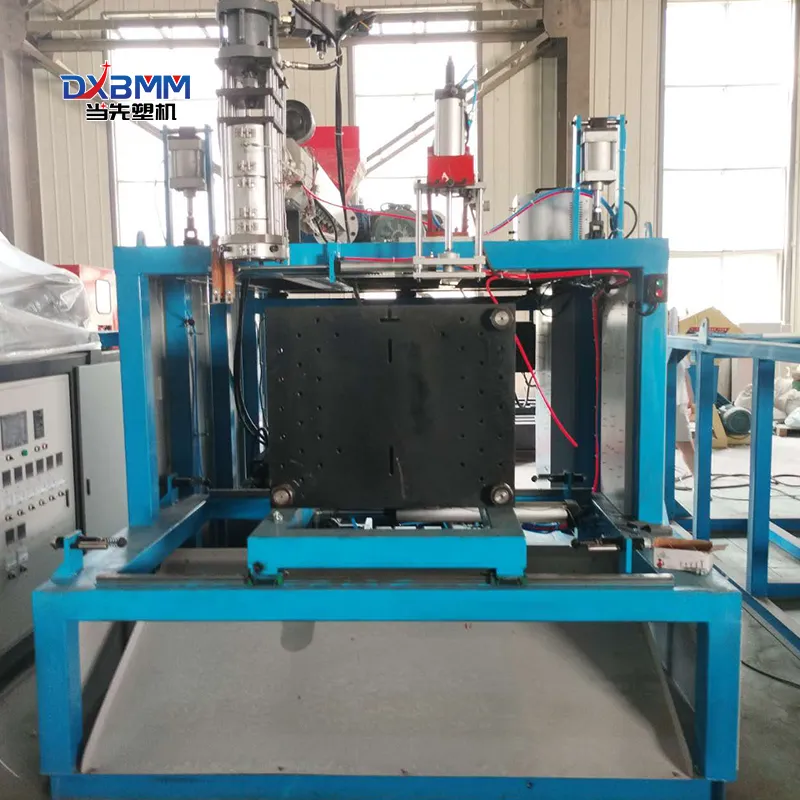

Type 80 Semiautomatic bottle blowing machine

Laundry liquid bucket

Type 80 Semiautomatic bottle blowing machine

| Number | Project | Parameter | Notes |

| 1 | 制品容量Product capacity | 5-10L | |

| 2 | 每模制品数量 | 2 modulus(模) | |

| Quantity of each molded product | |||

| 3 | 合模次数 | 每小时100-300次 | |

| Number of mold closures | 100-300 times/hour | ||

| 4 | 模板尺寸 | 500*500*50mm | |

| Template size | |||

| 5 | 最小容模厚度 | 200mm | |

| Minimum mold thickness | |||

| 6 | 模板最大开距 | 550mm | |

| Maximum template spacing | |||

| 7 | 最大锁模力 | 50KN | |

| Maximum locking force | |||

| 8 | 主机螺杆直径 | Ф8 | 38CrMoAl(劲威) |

| Main screw diameter | |||

| 9 | 螺杆长径比 | 25/1 | |

| Screw length to diameter ratio | |||

| 10 | 最大塑化能力 | 80kg | |

| Maximum plasticizing capacity | |||

| 11 | 主电机功率 | 18.5kw | 变频 |

| Main motor power | frequency conversion | ||

| 12 | 加温功率 | 20kw | |

| Heating power | |||

| 13 | 吹气方式 | 上吹气 | |

| Blowing method | Blow air upwards | ||

| 14 | 控制系统 | 触摸屏电脑PLC | 中达优控S700A |

| Control system | Touch screen computer PLC | Zhongda Youkong S700A | |

| 15 | 机组总质量 | 4T | |

| Total mass of the unit | |||

| 16 | 外形尺寸(长宽高) | 3.8m*2.1m*2.2m | |

| External dimensions (length, width, height) | |||

| 17 | 耗气量 | 0.5m3/min | |

| Gas consumption | |||

| 18 | 切料方式 | 热切料 | |

| Cutting method | Hot cut material | ||

| 19 | 电源 | 380v(三相四线制) | |

| source | Three phase four wire system | ||

| 20 | 液压电机 | 7.5kw | |

| Hydraulic motor | |||

| 21 | 液压系统hydraulic system | PVR2- 46 | 上海导德Shanghai Daode |

| 22 | 模头中心距 | ||

| Center to center distance of mold head | |||

| 23 | 整机加温段 | 5段 | |

| Whole machine heating section | 5 segments | ||

| 24 | 适用材料 | PE/PP | |

| Applicable materials | |||

| 25 | 锁模方式 | 中心直顶式 | |

| Locking mode | Center straight top type | ||

| 26 | 吹气压力 | 0.3-0.6MPA | |

| blowing pressure | |||

| 27 | 机筒、螺杆材质 | 舟山38CoMoAl | 渗氮处理 |

| Material of machine barrel and screw | Zhoushan | Nitriding treatment | |

| 28 | 变速箱Transmission | ZLYJ146 | 江苏惠鑫Jiangsu Huixin |

| 29 | 气动元件 | 白石气动 | |

| Pneumatic components | Baishi Pneumatic | ||

| 30 | 电磁阀 | BWIN | |

| Solenoid valve | |||

| 31 | 交流接触器电器 | 浙江正泰 | |

| AC contactor electrical appliances | Zhejiang Zhengtai | ||

| 32 | 接近开关 | 奥通米克 | |

| Proximity switch | Otomic | ||

| 33 | 电机 | 台州格欣 | |

| Electrical machinery | Taizhou Gexin | ||

| 34 | 变频器inverter | 18.5KW | |

| 35 | 模头Die head | 单 | |

| 36 | 油缸Oil cylinder | 80*400 | |

| 37 | 温控temperature control | 智能温控Intelligent temperature control | 上海亚泰Shanghai Yatai |

Suitable for hollow plastic products in fields such as medicine, toys, tool boxes, daily chemicals, automobiles, civilian buckets, and chemical buckets. Raw material PP PE

The machine mainly uses components

1. Industrial computer PLC: Zhongda Youkong S700A

2. Mold head: Zhangjiagang central feeding belt with diversion lock

3. Screw: Zhoushan Jinwei alloy screw

4. Reducer: Jiangsu Huixin

5. Oil pump: Panke

Overflow valve: Shanghai Daode

Directional valve: Shanghai Daode

6. Pneumatic system: Baishi Pneumatic

7. Electric control system: Chint Electric Appliances

Write your message here and send it to us